Description

Aprica BSP GO / NO-GO GAUGES

Includes calibration certificates

|

BSPNGP1 |

¼ x 19 tpi PLUG |

¼ x 19 tpi 3 STEP RING GAUGE |

|

BSPNGP2 |

3/8 x 19 tpi PLUG |

3/8 x 19 tpi 3 STEP RING GAUGE |

|

BSPNGP3 |

1/2 x 14 tpi PLUG |

1/2 x 14 tpi 3 STEP RING GAUGE |

|

BSPNGP4 |

3/4 x 14 tpi PLUG |

3/4 x 14 tpi 3 STEP RING GAUGE |

|

BSPNGP5 |

1” x 11 tpi PLUG |

1” x 11 tpi 3 STEP RING GAUGE |

Plug & Go & No-Go Ring Gauges

Quick How To Use Tips & Guide:

-

BSP threads are commonly used in plumbing and hydraulic systems. These threads have a specific pitch and diameter, and they must be within certain tolerances to ensure proper fit and seal.

-

Go/no go gauges, plugs, and rings are used to check the threads' accuracy and ensure they are within the correct tolerances. The go gauge checks the minimum allowable size of the thread, while the no-go gauge checks the maximum allowable size.

-

To use a go/no go gauge, first clean the threads to be checked. Place the go gauge onto the male thread or into the female thread. If the go gauge fits smoothly and completely, the thread is within tolerance. If the go gauge does not fit, the thread is too small and out of tolerance.

-

Next, place the no-go gauge onto the male thread or into the female thread. If the no-go gauge does not fit or only fits partially, the thread is within tolerance. If the no-go gauge fits completely, the thread is too large and out of tolerance.

-

To use a plug gauge, thread it into the female thread or place it over the male thread. The gauge should thread in easily and fit snugly without any wobbling. If the gauge does not thread in easily or wobbles in the thread, the thread is out of tolerance.

-

To use a ring gauge, place it over the male thread or into the female thread. The gauge should slide over the thread without any resistance and fit snugly without any wobbling. If the gauge does not slide over the thread or wobbles in the thread, the thread is out of tolerance.

-

It's important to note that these gauges are precision tools and should be handled with care. They should be stored in a protective case or pouch when not in use and cleaned regularly with a soft cloth to remove any debris or dirt.

-

Additionally, it's essential to use the correct gauge for the thread size being checked. Using the wrong gauge can lead to inaccurate results and potentially cause damage to the threads.

-

If the thread is found to be out of tolerance, it should not be used and should be replaced or repaired before use. This ensures proper fit and seal and avoids potential leaks or failures.

By following these steps, you can use BSP go/no go gauges, plugs, and rings to ensure the accuracy of threads and prevent issues in plumbing and hydraulic systems.

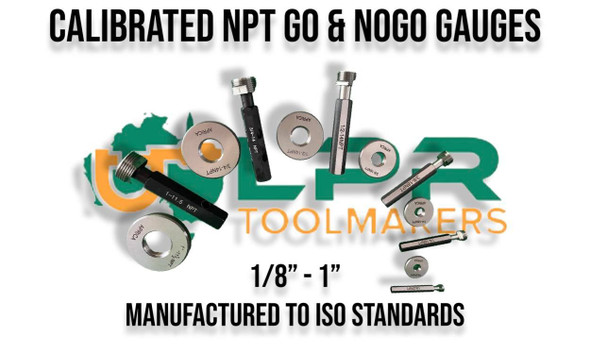

![NPT Go/No-Go Gauge - Plug & Ring Calibrated Set [1/8" to 1"] NPT Go/No-Go Gauge - Plug & Ring Calibrated Set [1/8" to 1"]](https://cdn11.bigcommerce.com/s-c9l4hm6h/images/stencil/590x590/products/4655/13949/NPT_Go-Nogo_12pc_Set_-_1__60090.1695268084.jpg?c=2)

![NPT Go/No-Go Gauge - Plug & Ring Calibrated Set [1/8" to 1"] NPT Go/No-Go Gauge - Plug & Ring Calibrated Set [1/8" to 1"]](https://cdn11.bigcommerce.com/s-c9l4hm6h/images/stencil/590x590/products/4655/13950/NPT_Go-Nogo_12pc_Set_-_2__32481.1695268085.jpg?c=2)