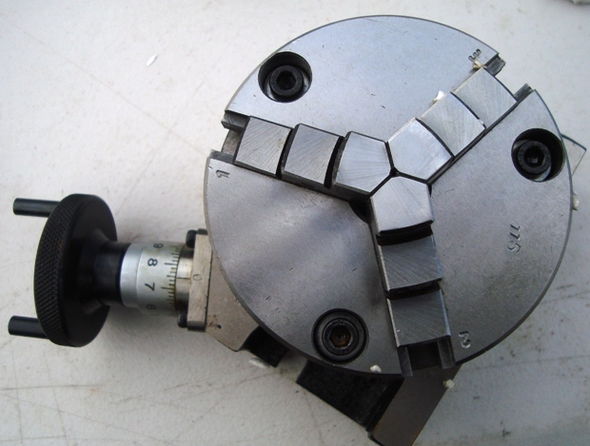

Revolving 3 Jaw Self Centering Chuck - 100mm OD mounted on 3MT, 4MT or 5MT Rotating Arbor

- SKU:

- SKU-CHBED100

- Availability:

- If in stock (Please see below price for current stock level) - Ships same day if ordered between Monday-Friday & before 3.30PM Victorian time.

- Shipping:

- Calculated at Checkout

Description

3 Jaw Self Centering Chuck - 100mm OD with mounted MT Rotating live centre

(You Pick your required Arbor Size from 3MT, 4MT or 5MT)

About this Unit:

The chuck plate is designed to support the 3-jaw self centring lathe chuck. These Arbors are made of high quality steel and hardened for high performance and stability. They arbors are also a heavy duty triple ball bearing design.

This unit offers several benefits in various machining and work holding applications.

Here are some of the advantages:

-

Self-Centring: The primary advantage of a self-centring chuck is its ability to automatically centre and securely hold a workpiece without the need for manual adjustment. This saves time and ensures consistent accuracy when clamping different-sized workpieces.

-

Quick Setup: Setting up a self-centring chuck is quick and straightforward. You simply place the workpiece in the chuck, close the jaws, and it automatically centres and clamps the workpiece.

-

High Precision: Self-centring chucks are known for their precision. They can hold workpieces with high concentricity, which is essential for tasks like turning, milling, and grinding, where accurate machining is crucial.

- Versatility: With a 3-jaw chuck, you can hold both round and hexagonal workpieces, making it versatile for a wide range of applications. The 100mm OD provides a good size range for accommodating various workpiece diameters.

- Secure Grip: The jaws of the chuck provide a strong and secure grip on the workpiece, reducing the risk of slippage or movement during machining operations.

-

Reduced Setup Time: Self-centring chucks can significantly reduce setup time compared to traditional independent-jaw chucks, where each jaw needs to be adjusted individually.

-

Compatibility with Live Centre: The inclusion of a mounted Morse Taper (MT) Rotating Live Centre further enhances the chuck's capabilities. The live centre supports the workpiece at the tailstock end, providing additional stability and reducing vibration during machining, which is particularly important for long workpieces.

-

Increased Productivity: The combination of self-centring chuck and live centre improves productivity by allowing for faster workpiece changes and reducing the need for constant adjustments.

- Safety: Self-centring chucks are generally considered safer to use, especially for less experienced machinists, as there is less risk of improper clamping.

-

Consistency: Once set up, a self-centring chuck provides consistent results, ensuring that machined parts meet the required specifications and tolerances.

Such a valuable tool in machining and work holding as these units combine the benefits of precision, ease of use, versatility, and compatibility with live centres to enhance productivity and machining accuracy.